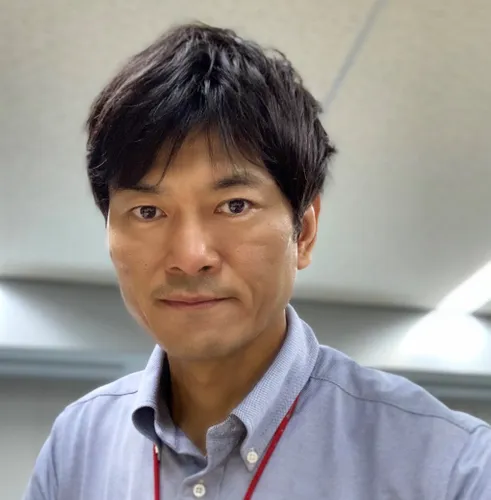

JGC has designed and built plants that account for over 30% of current global LNG production. What role does technology play in increasing the cost competitiveness of LNG projects and what measures can be put in place to lower the carbon intensity of LNG production?

JGC leverages its extensive experience and knowledge in the LNG field to provide AIRLIZE LNG technology. Air-cooled LNG plants have the problem of degraded plant performance due to the influence of surrounding weather, so we offer a compact plant design by making full use of our unique innovative air control AIRLIZE LNG technology. A compact plant helps reduce costs. In addition, our technology increases production efficiency and improves fuel efficiency, making it possible to achieve low carbon emissions. By leveraging our extensive experience in LNG plant design and operation, our engineers analyze operational data for plants with flaring issues and support the achievement of Zero Flaring.

JGC is aiming for carbon neutrality by 2050 with a critical focus on emissions abatement. Effective measurement and standardized reporting of GHG emissions is critical to achieving net zero goals, and in 2023, JGC became the first Japanese company to join the OGCI’s Aiming for Zero Initiative, supporting an industry-wide effort to eliminate methane emissions from oil and gas operations. How is JGC using technology to improve methane emissions measurement what impact is this having across your projects?

JGC is the first Japanese company to participate in the Aiming for Zero Methane Emissions Initiative promoted by OGCI. We are supporting Japanese government agency JOGMEC in developing guidelines for calculating GHGs associated with LNG, hydrogen, and ammonia production, and also measuring GHG emissions at an ammonia production plant in Indonesia focusing on methane. We have worked to develop methane measurement methodology and improve technology related to methane MRV. We believe that our participation in this initiative is the result of recognition of OGCI activities. We view the reduction of methane emissions as one of the important steps toward carbon neutrality, and JGC is accelerating our efforts toward a carbon-neutral society by 2050.

In addition, JGC has built a methane emission measurement technology evaluation facility at our Research & Development Center providing a place for domestic and foreign measurement equipment manufacturers to evaluate the detection ability and develop technology for methane emission measurement technology, which is still in the process of being developed worldwide. JGC is working to realize effective measures against methane emissions by improving measurement technology through wide-ranging collaboration.

JGC has built a reputation as a leading contractor in Carbon Capture and Storage (CCS), with plans for a permanent CO₂ storage project offshore Malaysia recently announced with Petronas, JAPEX and K Line. How is JGC continuing to actively develop and invest in CCS technologies to both capture and utilize CO₂? What trends do you think we’ll see across CCS in 2024?

The trend of decarbonization is accelerating globally and the demand for energy is increasing, especially in emerging countries, and expectations are rising for CCS as a technology that can solve these two issues. JGC has a rich track record and a wide range of technologies and is working to reduce the environmental impact of fossil energy by promoting CCS.

Since completing the CCS facility construction in Algeria in 2004, JGC has had a track record of constructing one of the world's largest CCS facilities for an LNG plant in Australia, alongside the completed construction of Japan's first large-scale CCS facility. In addition to the construction of facilities, we are also actively developing technology related to CO₂ separation technology, including a unique CO₂ separation and recovery technology using DDR-type zeolite membranes and HiPACT which is a high-pressure regenerative CO₂ recovery process with excellent CO₂ absorption performance.

JGC is also aiming to build a CCS value chain with partners in Asia and are working to realize a decarbonized society in Asia by building an international CCS value chain in Malaysia, Indonesia, Thailand, and other countries.

Hydrogen is now positioned to become a vital part of the future energy mix as efforts accelerate towards the development and adoption of low carbon fuel alternatives; however, its safe storage and transportation remains an industry-wide challenge. What technological advancements has JGC made in enabling the practical adoption of commercial-scale hydrogen carriers?

JGC is focusing on ammonia as a hydrogen carrier. In order to accelerate efforts toward the social implementation of fuel ammonia, JGC is playing a key role in the CFAA, a collaboration between private companies and the Japanese government, and is working to build a value chain from supply to utilization of fuel ammonia.

JGC is constructing a green ammonia production plant that uses hydrogen derived from renewable energy and is developing a system that will compensate for fluctuations in power supply derived from renewable energy and achieve operational optimization. We are also developing technology to produce hydrogen by decomposing ammonia and are working to produce hydrogen from ammonia imported as a hydrogen carrier.

How important are collaborations and partnerships with industry, governments, and universities in driving technological innovation and R&D at JGC? What recent partnership has made a significant impact on your long-term strategy?

JGC aims to solve global issues by actively working to build a value chain with key technologies that contribute to sustainability, encouraging behavioral changes in consumers, and establishing an ecosystem.

When building a value chain, JGC will not only use technologies developed and owned by our own group, but also consider collaboration with companies that possess various cutting-edge technologies and open innovation with universities, as well as collaboration with government agencies, local governments, and companies.

Our group also aims to establish an ecosystem through changes in consumer behavior. As a specific initiative to encourage behavior change, JGC asked companies and local governments to cooperate in reusing used cooking oil as SAF with the aim of large-scale production of domestically produced SAF. Additionally, in order to build an ecosystem for the textile industry, we promoted demonstrations of clothing collection and recycling through collaboration with companies and other organizations.

You and your fellow Governing Body members are currently in the process of peer-reviewing the technical and commercial abstracts submitted through the Gastech Call for Papers. What trends and insights are you hoping to see emerge across the Technical and Commercial conference at Gastech 2024?

Due to the globally accelerating trend of decarbonization and the increase in energy demand, the decarbonization of fossil fuels is an important issue that must be advanced simultaneously.

The papers submitted to Gastech every year challenge these issues. This is a valuable opportunity to learn about the trends and insights of pioneers. At this year's Papers, I look forward to breakthrough innovations and inspiring visions that can accelerate climate action and create a more sustainable transition.

What are you most looking forward to at Gastech 2024?

This year's Gastech will be held in Houston, the world's largest concentration of energy companies, so I look forward to seeing announcements that lead to concrete actions to accelerate the energy industry's global vision towards carbon neutral.